which is the diffraction wavelength limit for any grating. Plugging these values into the grating equation yields λ = 2d. The highest angle of diffraction achievable is 90 degrees. The highest angle of incidence (i) achievable is 90 degrees (sin 90 = 1). The longest wavelength that a grating can diffract (the diffraction limit) is equal to 2 times the spacing.Every allowable integer value of n will provide a different wavelength. There is no unique solution for λ, for a given set of angles.I’ = angle of diffraction with respect to grating normal I = angle of incidence with respect to grating normal The equation that dictates the diffraction properties of a grating is given by: The blaze angle has absolutely no bearing on the diffraction angle at any wavelength. The angle made by a groove’s longer side and the plane of the grating is the “blaze angle.” The blaze angle for a blazed grating is generally the biggest factor in determining where the efficiency curve peaks under a certain set of conditions. The grooves of a ruled grating have a saw tooth profile with one side longer than the other. These gratings combine the beneficial low stray light properties of holographic grating with the high efficiency of ruled gratings. Special techniques can be employed to give some holographic gratings an asymmetric profile, and hence, blaze properties. This explains why some symmetric holographic gratings can achieve greater than 50% absolute efficiency in a given order, although most do not.

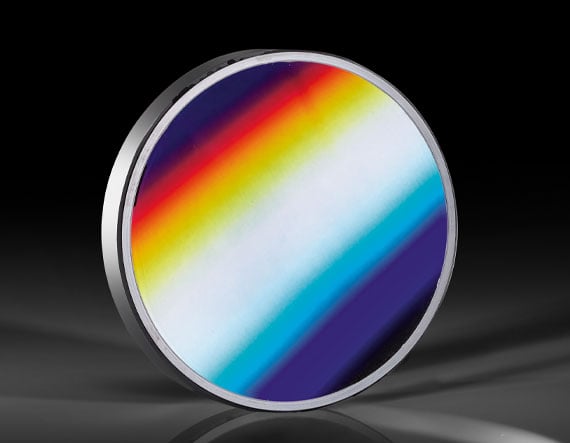

Most holographic grating masters are generated initially with a symmetric groove profile. It is important to note that a symmetric profile holographic diffraction grating will only have symmetry in efficiency on either side of zero order when the light is incident at 0 degrees (normal incidence). Blazing is not as easy with holographic gratings however, and with certain notable exceptions, they will not be as efficient as ruled, blazed gratings. Holographic master gratings generally exhibit better stray light properties than ruled master gratings. The addition of a reflective overcoat completes the process. After development, the sinusoidal variation in light intensity during exposure is transformed into a physical structure of the same profile. The resulting interference pattern differentially exposes the photoresist. Holographic master gratings are produced by exposing a thin layer of photoresist to 2 intersecting coherent, monochromatic beams. The resulting profile will show some peak round-off, and not achieve theoretical depth. Actual groove depth is typically 90% of theoretical. As a result, there is some displacement and deformation of the material on the short facet into the previously ruled groove every time a new groove is formed. Rather, the coating is burnished by the tool. When a master ruled grating is generated, the diamond tool does not actually remove material and cut a theoretically shaped groove. The calculated theoretical groove depth is given as: Theoretical Profile of a Ruled Blazed Grating Because of the mechanical nature of the mastering process however, there can be random and periodic spacing errors that could detract from the purity of the diffracted spectra. Ruled blazed gratings are very efficient, and are generally the best choice for applications requiring high signal strength. The resulting groove profile has a well defined and controllable groove profile that directs energy efficiently into the desired wavelength range. The master gratings are produced by forming the surface of a soft metallic coating with a diamond form tool. Types of Diffraction Gratings Ruled, Blazed Diffraction Gratings Every wavelength undergoes a different phase shift, and as a result, diffracts at a different angle, resulting in a dispersion of broadband light. This redirection (or diffraction) is a result of the phase change of the electromagnetic wave as it encounters the regular, fixed structure of the grating surface. A diffraction grating is a passive optical component that redirects light incident upon the surface at an angle that is unique for every wavelength in a given order.

0 kommentar(er)

0 kommentar(er)